AI-Led Manufacturing in Industry 4.0

The Internet of Things (IoT) brought in an unprecedented tsunami of structured and unstructured data. Information, in conjunction with the easily available inexpensive computing systems, paved the way for the next level of manufacturing. AI, being the flagbearer of the transition, plays a vital role.

A village cobbler performs all shoe manufacturing-related tasks on her own – from design, manufacturing, and repair to reuse. Ameri and Dutta cited this crisp model as an ideal example of an integrated and competence-centered enterprise.

The all-efficient cobbler’s model, however, becomes un-pragmatic in scaled-up enterprises. In heterogeneous decentralized organizations, getting information and ideas on the same page is a major challenge. Aside from operational impediments, it greatly hampers innovation.

This bottleneck plagued enterprises for centuries. They worked assiduously in silos to arrive at a holistic solution.

In their own limitations, manufacturing giants like Land Rover, P&G, Johnson & Johnson, Unilever, and Rolls-Royce unearthed the panacea for this puzzle by introducing PLM in their systems.

As Industry 4.0 deepens its roots, now the PLM model is increasingly getting replaced by AI-led PLI. In this article we try to decode the how and why of it.

A Brief Backdrop

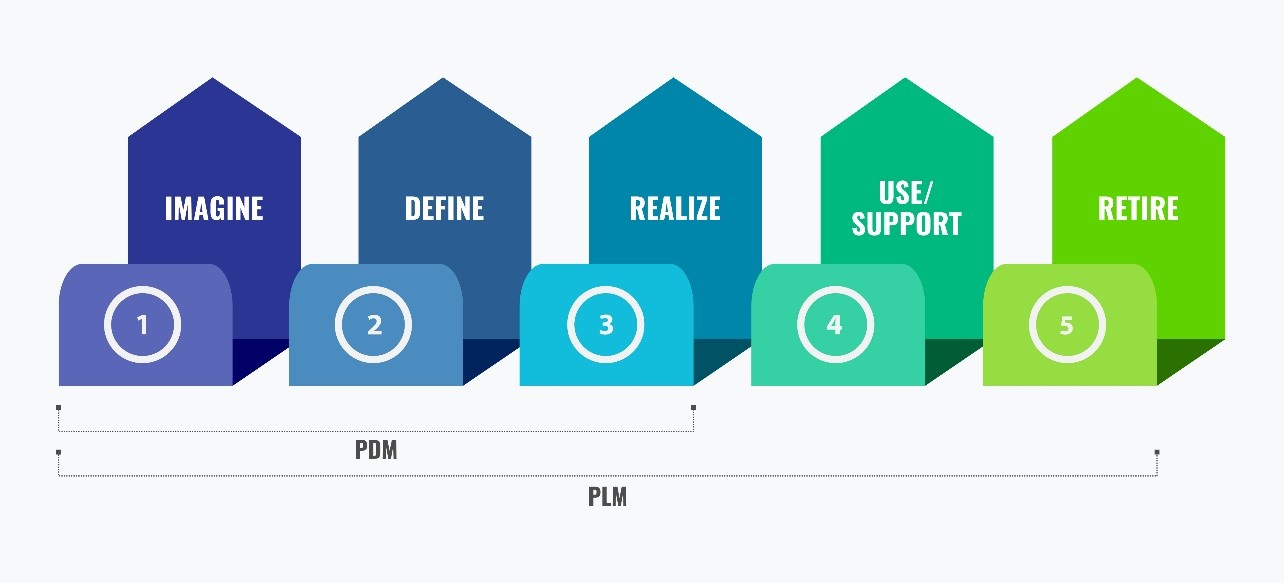

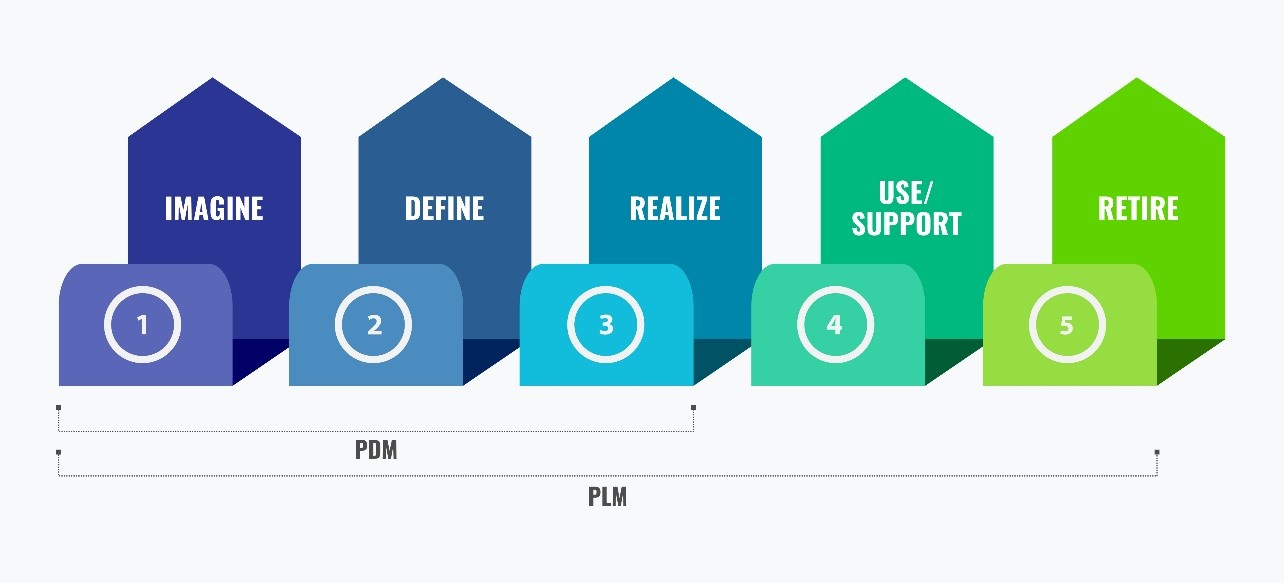

Somewhere around the 1980s, engineers recognized the need for data discernment. They conceptualized an umbrella of independent process supplements: Computer-Aided Design (CAD), Computer-Aided Manufacturing (CAM), and Computer-Aided Engineering (CAE). They had a name for this cohort – they called it Product Data Management (PDM).

But soon they realized that data alone was incapable of delivering holistic insights, so they extended their efforts to the entire product lifecycle, marking the birth of Product Lifecycle Management (PLM).

PLM was a major upgrade on PDM. It was a unified set of software tools shaping design, inspection, and manufacturing of products.

PLM systems used the same set of data for all transactions, improving data integrity and thereby minimizing errors.

As AI is revamping most businesses, it is reinventing PLM too.

PLI “is an evolution of PLM that applies artificial intelligence and automation to help PLM users extract meaningful insights from product data, formulate predictions, recommend improvements, and automate actions within systems and processes.” – Kalypso

How Product Lifecycle Intelligence (PLI) Improves Product Lifecycle Management (PLM):

PLM systems collated data from various stages in the product lifecycle – user behavior, specifications, seasonality, materials, and more. An annex to human intuition, PLM-related data was a consistent contributor to innovation and operational improvements…

…until the explosion of data brought forth its own set of challenges, ranging from:

Massive volumes of jumbled data; and

Storage, analysis and communication difficulties; to

Extracting information from the data

Also, to function rightly, PLM needed to integrate information from supplementary sources like manufacturing execution system (MES), enterprise resource planning (ERP), and customer relationship management (CRM).

Artificial Intelligence came to the manufacturing companies’ aid here.

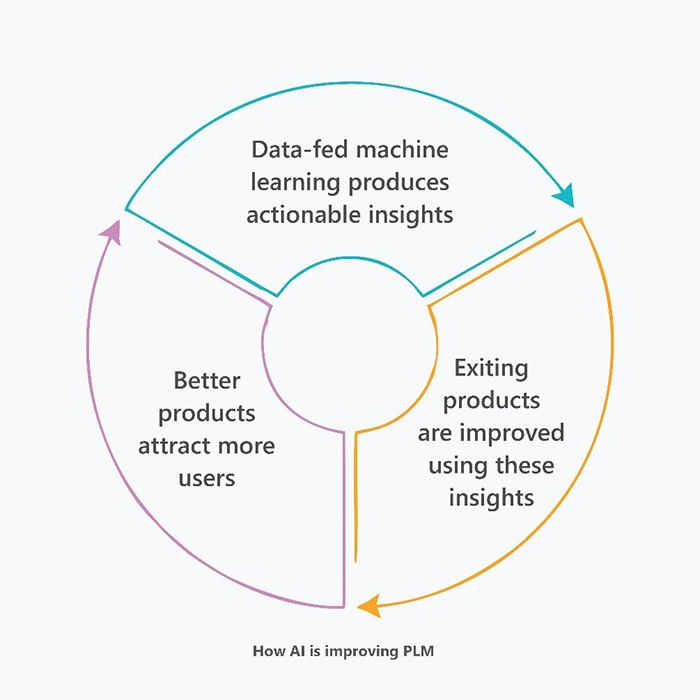

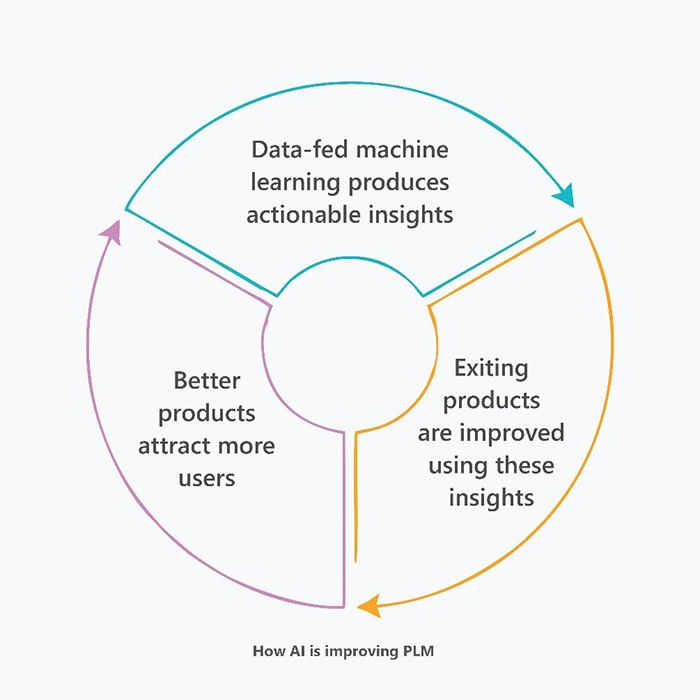

Using the data, the machine learning algorithms uncover facets invisible to the human eye and inject insights into the product lifecycle.

Digitalization of PLM is at nascent stages but even the constricted current developments are showing promising results.

AI is assisting conventional PLM in five ways:

# Increasing Design Productivity

Adaptive interfaces can lead the way for designers. By predicting the next steps and informing the user accordingly, machine learning can greatly increase design productivity. It can also up the design experience by giving the users the freedom to customize the user interface.

BMC’s Autonomous Digital Enterprise is using AI to deliver next-gen business models.

Nissan’s 2016 pilot program DriveSpark, which used AI for fast-track vehicle design, was hugely successful. The automotive behemoth is using it to accelerate its new vehicle development.

#Easing Supply Chain Bottlenecks

Faster time-to-market can create a significant competitive advantage. Machine learning can chew the supplier data to churn out best suppliers, factoring in all aspects: location, competitive costs, historical performance, and reputation.

Honeywell is using AI and ML to procure, source, and compare its suppliers for the new product development process. The process is already yielding impressive returns.

#Continuous Improvement

Machine learning can sift through historical sales data and unfiltered customer responses to pull out relevant insights. These insights can be used to make important alternations or additions to the product. Akin to virtual prototyping, machine learning can pick the option with the bulkiest chunk of gross margin from a stacked pile of millions of options.

AI’s next-gen frameworks reduce time-to-market while simultaneously working on improving product quality and customization.

# Intent Identification

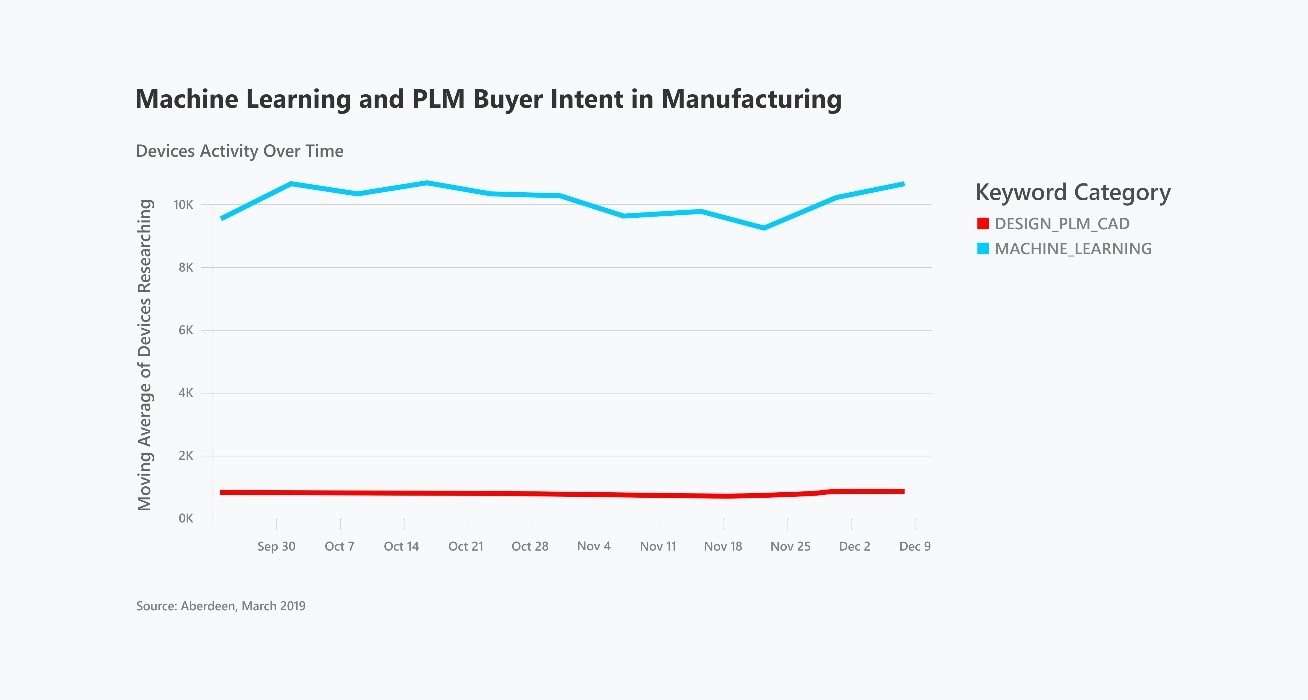

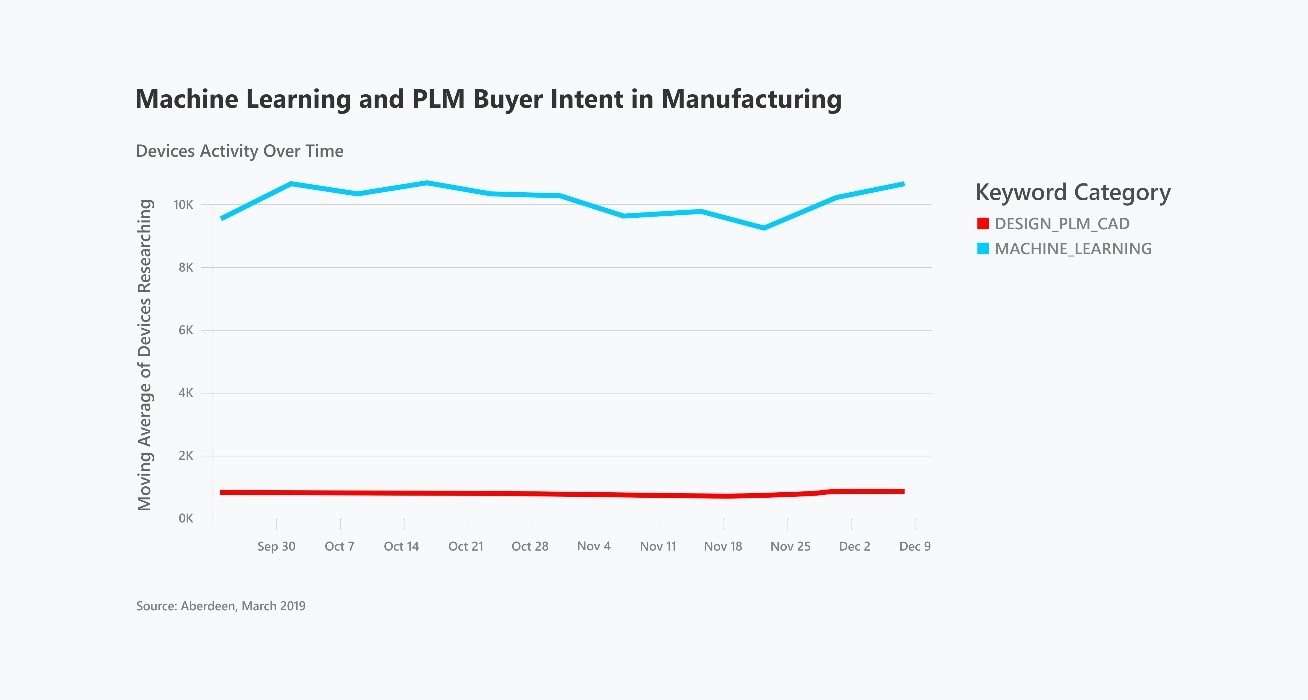

From the vast universe of varied data of Internet browsers, machine learning can track user behavior and intent.

“AI is streamlining creation, finetuning, and revenue contributions of up-sell and cross-sell strategies by automating the entire process.” – Forbes

Proof of Concept

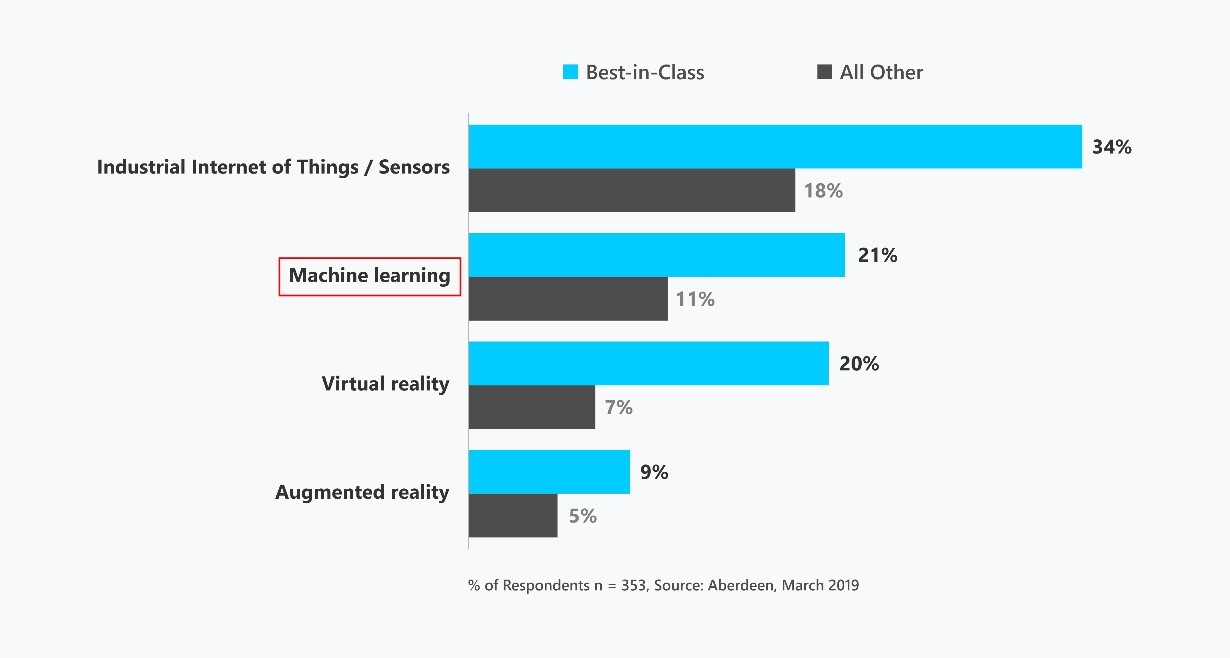

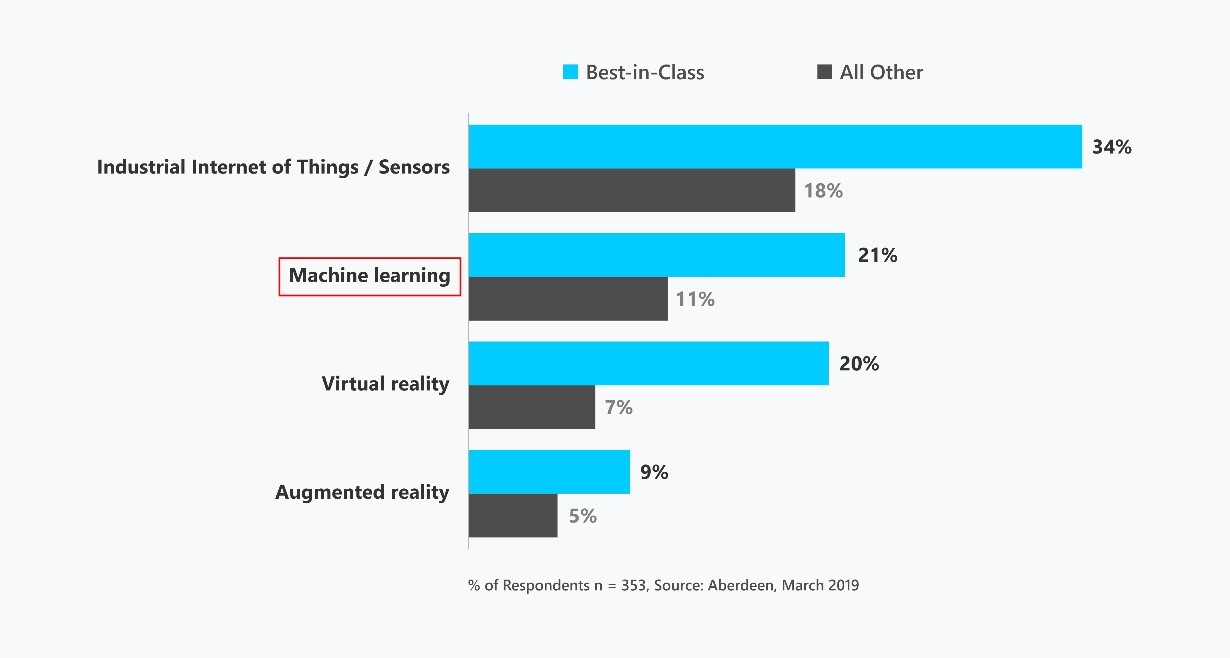

Aberdeen, in its 2019 study of 353 manufacturing firms, found almost twice as many Best-in-Class firms using machine learning as the average ones.

14% of the most advanced enterprises use AI and ML for new product development. – PwC

“61% of enterprises who are the most advanced using AI and ML (Digital Champions) use fully-integrated Product Lifecycle Management (PLM) systems compared to just 12% of organizations not using AI/ML today (Digital Novices).” – Forbes

AI-Led Manufacturing in Industry 4.0

Product design, repair, and management date back to the early days of human civilization. They have evolved into complex and knowledge-intensive projects however; the basic tenants remain the same

Determine the set of needs of the customers >Develop products that satisfy those needs

85% of customers expect the companies to understand their priorities and personalize their deliverables. – Forrester

Who can give better insights than AI?

Trivia

The earliest recorded application of PLM dates back to 1985, by American Motors Corporation.

By 2023, the PLM market will exceed USD 60 billion.